In recent years, schools across the country have increasingly opted for prefabricated rubber running tracks for their sports fields. This shift is largely due to the numerous benefits these running tracks offer over traditional surfaces. NWT Sports, a leading provider of high-quality prefabricated rubber running tracks, is at the forefront of this trend, providing schools with durable, safe, and high-performance athletic surfaces. This article explores why schools are choosing synthetic artificial running track from NWT Sports and the advantages they bring to educational institutions.

Enhanced Safety for Students

One of the primary reasons schools are turning to prefabricated rubber tracks is the enhanced safety they provide for students. NWT Sports' tracks are designed with superior shock absorption, reducing the impact on athletes' joints and minimizing the risk of injuries. This is particularly important for younger athletes whose bodies are still developing. The non-slip surface of these tracks also ensures better traction, even in wet conditions, further reducing the risk of slips and falls.

Durability and Longevity

NWT Sports' prefabricated rubber tracks are renowned for their durability. Made from high-quality recycled rubber and advanced binding agents, these tracks are built to withstand heavy use and extreme weather conditions. Unlike traditional asphalt or concrete surfaces, rubber tracks do not crack or wear down quickly, offering schools a long-term solution that remains in excellent condition for many years. This durability translates to lower maintenance costs and fewer disruptions due to repairs.

Cost-Effectiveness

While the initial investment in prefabricated rubber tracks might be higher than traditional options, the long-term cost savings are significant. NWT Sports tracks require minimal maintenance compared to other surfaces, which means schools save money on repairs and upkeep. Additionally, the longevity of these tracks means schools do not need to replace them as frequently, making them a more economical choice over time.

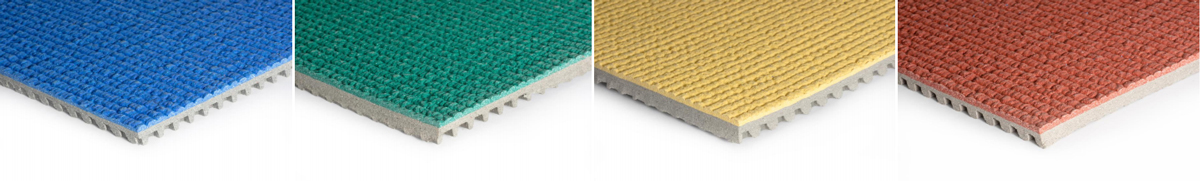

Prefabricated Rubber Running Track Color Card

Environmental Benefits

NWT Sports is committed to sustainability, and their prefabricated rubber tracks reflect this commitment. Made from recycled materials, these tracks help reduce waste and lower the environmental impact. Schools that choose NWT Sports tracks can promote their commitment to environmental stewardship, a value increasingly important to students, parents, and the community.

Improved Athletic Performance

Athletes perform better on high-quality surfaces, and NWT Sports’ prefabricated rubber tracks are designed to enhance performance. The even, consistent surface provides optimal traction and energy return, helping athletes run faster and train more effectively. For schools, this means better results in competitions and a more enjoyable experience for students participating in track and field activities.

Quick and Efficient Installation

The installation process for NWT Sports' prefabricated rubber tracks is streamlined and efficient. Prefabricated sections are manufactured in a controlled environment and then transported to the site for quick assembly. This reduces the installation time and minimizes disruptions to the school’s schedule. Schools can have their new track up and running in a matter of days, ready for use by students and athletes.

Customizable Options

NWT Sports offers a range of customizable options to meet the specific needs of each school. From different colors and markings to varying thicknesses and surface textures, schools can choose a track that perfectly suits their requirements. This level of customization ensures that each track not only meets safety and performance standards but also enhances the aesthetic appeal of the school’s sports facilities.

Conclusion

Schools are increasingly choosing prefabricated rubber tracks from NWT Sports for their sports fields due to the numerous advantages they offer. Enhanced safety, durability, cost-effectiveness, environmental benefits, improved athletic performance, quick installation, and customizable options make these tracks the ideal choice for educational institutions. NWT Sports continues to lead the way in providing high-quality, sustainable athletic surfaces that meet the evolving needs of schools and their students.

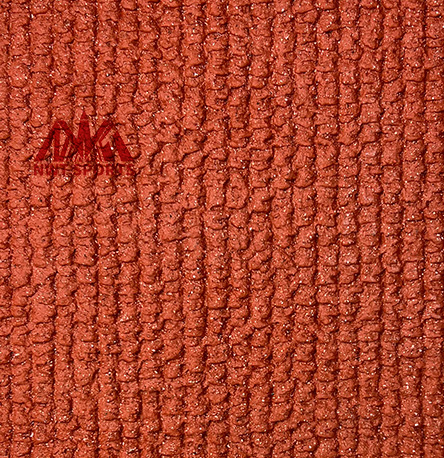

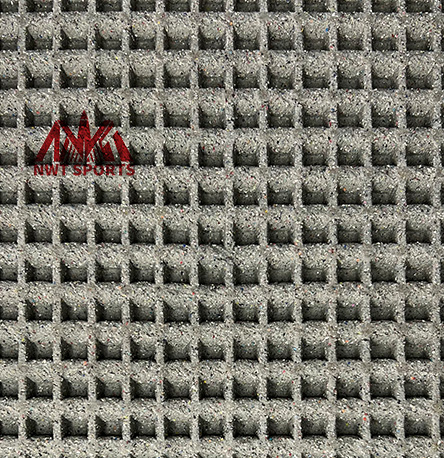

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jul-23-2024