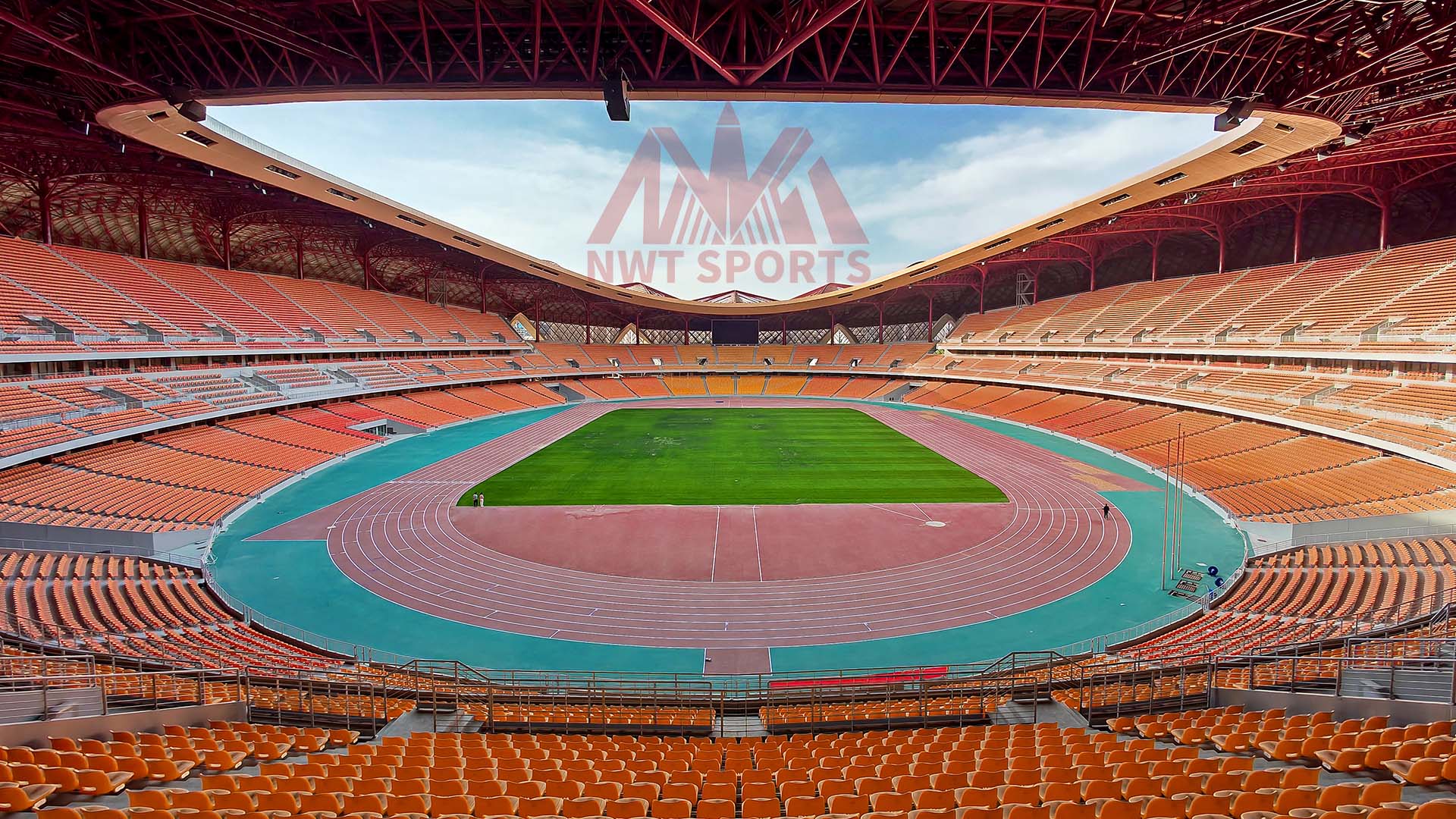

In recent years, the urban landscape has undergone significant transformations, with city parks evolving from simple green spaces into multifunctional recreational areas. One of the emerging trends in this transformation is the adoption of prefabricated rubber running tracks, particularly in city parks. This article explores how NWT Sports is leading this trend with its innovative prefabricated rubber running track solutions and what makes them a top choice for urban planners and communities.

Why Prefabricated Rubber Running Tracks?

Prefabricated rubber running tracks offer several benefits over traditional track materials, making them an ideal choice for urban parks:

· Enhanced Safety: Prefabricated rubber running tracks are designed to provide excellent shock absorption, reducing the risk of injuries during athletic activities. This feature is especially beneficial in urban parks where diverse age groups and activity levels are present.

· Durability and Low Maintenance: Made from high-quality rubber, these tracks are highly resistant to wear and tear. They can withstand various weather conditions without losing their functionality, significantly reducing maintenance costs and extending the lifespan of the track.

· Environmental Benefits: NWT Sports' prefabricated rubber running tracks are made from recycled materials, contributing to environmental sustainability. By incorporating these tracks into city parks, urban areas can promote eco-friendly practices and contribute to green initiatives.

NWT Sports: Leading the Way

NWT Sports is at the forefront of the prefabricated rubber running track industry, offering cutting-edge solutions that are transforming city parks across the globe. Here’s why NWT Sports stands out:

· Innovative Technology: NWT Sports utilizes advanced manufacturing techniques to produce high-quality prefabricated rubber running tracks. Their products are engineered for optimal performance, including superior shock absorption and durability.

· Custom Solutions: Understanding that every park has unique needs, NWT Sports provides customizable track designs to fit specific park layouts and user requirements. This flexibility ensures that each installation meets the highest standards of safety and functionality.

· Proven Track Record: NWT Sports has successfully completed numerous projects, showcasing their expertise in integrating prefabricated rubber running tracks into urban environments. Their portfolio includes parks of all sizes, demonstrating their ability to deliver high-quality results consistently.

The Future of Urban Parks with Prefabricated Rubber Running Tracks

The integration of prefabricated rubber running tracks in city parks is more than just a trend; it's a strategic move towards creating safer, more durable, and environmentally friendly recreational spaces. As urban areas continue to grow and evolve, the demand for innovative solutions like those offered by NWT Sports will likely increase.

City planners and park developers are increasingly recognizing the advantages of incorporating these advanced tracks into their designs. With the support of NWT Sports, urban parks are not only becoming more functional but also enhancing the overall quality of life for residents.

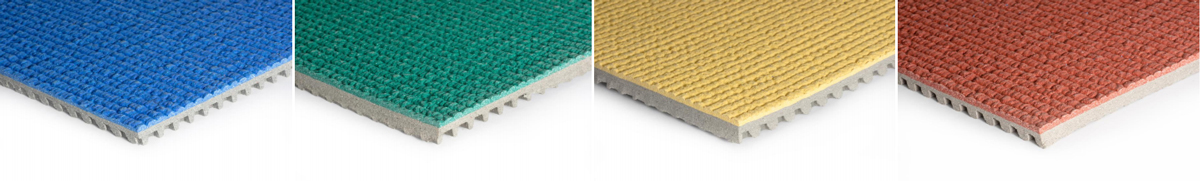

Prefabricated Rubber Running Track Color Card

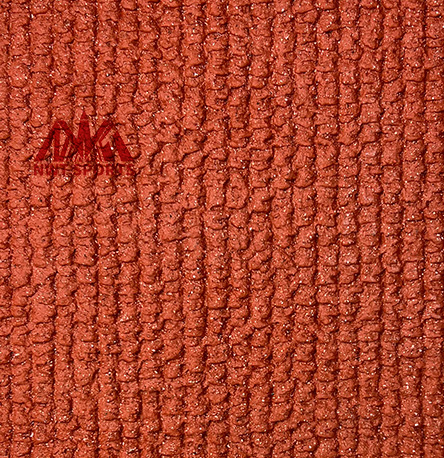

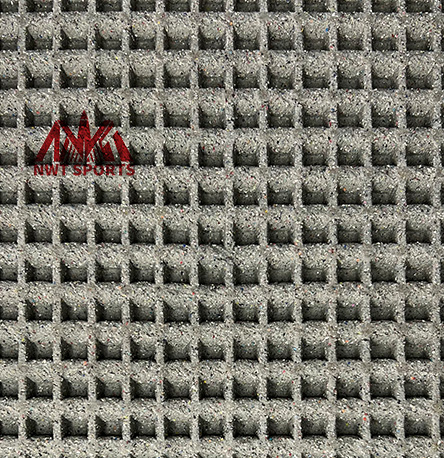

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jul-19-2024