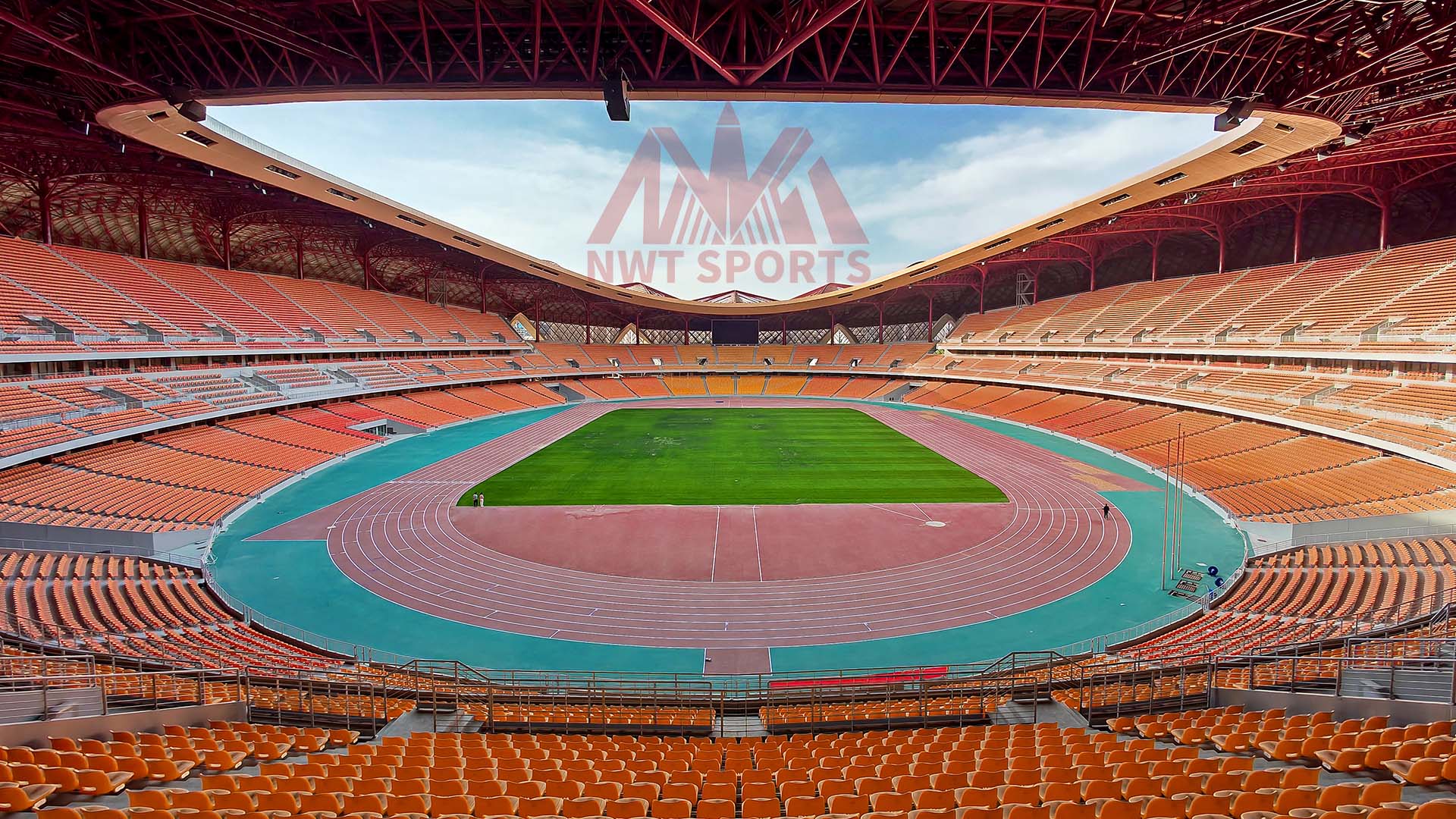

Athletic tracks play a crucial role in a wide range of sports and physical activities. Whether for professional competitions or community events, the design and surface material of a track directly influence performance, safety, and durability. In this article, we’ll dive into the standard dimensions of an athletic track, explore the features of a rubberized track oval, and highlight the importance of proper lane design in ensuring optimal conditions for athletes. All these topics are central to our expertise at NWT Sports, where we specialize in creating premium-quality track surfaces.

How Many Meters is a Track?

A common question we receive at NWT Sports is, “How many meters is a track?” The standard running track used in most athletic competitions, including the Olympics, measures 400 meters in length. This distance is measured along the innermost lane of the track, following its elliptical shape. A standard track consists of two parallel straight sections connected by two semi-circular bends.

Understanding the exact length of a track is essential for both athletes and coaches, as it directly impacts the planning and pacing of training sessions. For instance, a runner’s lap time on a standard 400-meter track will differ from that on a shorter or longer track. At NWT Sports, we ensure that all tracks we design meet the necessary international regulations to provide athletes with the best training and competition environments.

Rubberized Track Ovals: What Are They and Why Choose Them?

When it comes to track surfaces, a rubberized track oval is one of the most popular choices in modern athletics. These tracks are known for their smooth, shock-absorbing properties, which make them a superior option compared to traditional asphalt or cinder tracks.

Rubberized track ovals are constructed using a blend of synthetic rubber and polyurethane, resulting in a highly durable, weather-resistant surface. The rubberized surface provides optimal traction for athletes, reduces the risk of injury by absorbing impact, and enhances overall performance. Whether sprinting or running long distances, athletes benefit from the cushioning effect that reduces stress on joints and muscles.

At NWT Sports, we specialize in constructing high-quality rubberized track ovals for a variety of venues, including sports fields, schools, and public parks. Our tracks are built to meet both international standards and specific client needs, ensuring that every track is safe, durable, and ready for high-performance use.

What is a Standard Athletic Track?

A standard athletic track is defined by specific dimensions and guidelines set by governing bodies like the International Association of Athletics Federations (IAAF). The typical track, as mentioned earlier, is 400 meters in length and features 8 to 9 lanes, each with a width of 1.22 meters. The straight sections of the track are 84.39 meters long, while the curved sections form the remainder of the distance.

In addition to running lanes, a standard athletic track also includes areas for field events like long jump, high jump, and pole vault. These events require designated zones and facilities adjacent to the track.

At NWT Sports, our focus is not just on creating high-performance running surfaces but also on ensuring that every element of the standard athletic track is designed for maximum functionality. Whether for schools, professional stadiums, or public facilities, our tracks are engineered to offer excellent performance in all weather conditions.

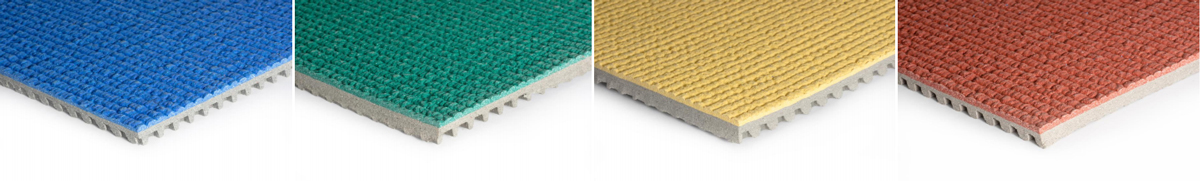

Prefabricated Rubber Running Track Color Card

Track Lanes: Importance of Design and Layout

The track lanes are an essential component of any athletic track, and their design can significantly affect race results and training efficiency. Each lane on a standard track has a specific width, and for competitions, athletes are usually assigned to a single lane to run their race. The lanes are numbered from the inside out, with the innermost lane being the shortest in distance due to the elliptical design of the track.

To ensure fairness in races, staggered starting lines are used in sprint races where athletes must run around the curves. This compensates for the longer distance in the outer lanes, allowing all athletes to cover an equal distance.

Proper lane markings and a high-quality surface are essential for reducing injury risks and providing athletes with a clear path to follow. NWT Sports takes pride in ensuring that our track lanes are designed to meet the highest standards of accuracy and safety. We use durable, wear-resistant materials to mark the lanes, ensuring they remain visible and reliable even after extended use.

The Advantages of Choosing NWT Sports for Your Track Construction

At NWT Sports, we understand the importance of precision, quality, and durability in track construction. Whether you need a rubberized track oval for a high-performance sports complex or a standard athletic track for a school, our team is dedicated to delivering top-tier solutions. Here are a few reasons why NWT Sports is a leader in track construction:

1. Customized Solutions: We tailor every project to the specific needs of our clients, ensuring that the track design meets both regulatory standards and the unique requirements of the venue.

2. Premium Materials: Our rubberized tracks are built with the highest-quality materials to ensure longevity, safety, and performance under various weather conditions.

3. Expert Installation: With years of experience, our installation team guarantees that your track will be ready for use on time and within budget, without compromising quality.

4. Sustainability: We are committed to environmentally friendly practices. Our materials are selected not only for their performance but also for their minimal environmental impact.

Conclusion

Whether you're wondering, "how many meters is a track" or interested in constructing a rubberized track oval, understanding the dimensions, materials, and design of a track is critical to its success. At NWT Sports, we bring years of experience in creating world-class standard athletic tracks and track lanes that meet the highest standards of quality and safety. Our tracks are built to enhance athletic performance while ensuring long-term durability and minimal maintenance.

For more information on how NWT Sports can help you with your track construction or to get a quote for your next project, contact us today.

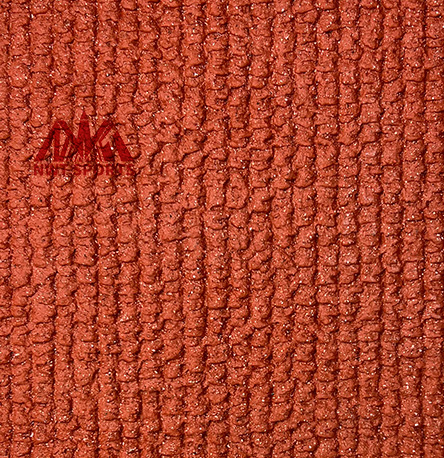

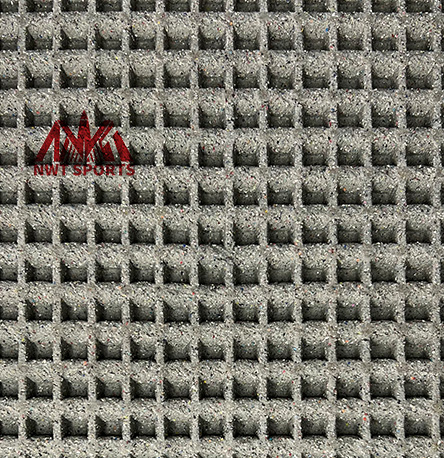

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Sep-14-2024