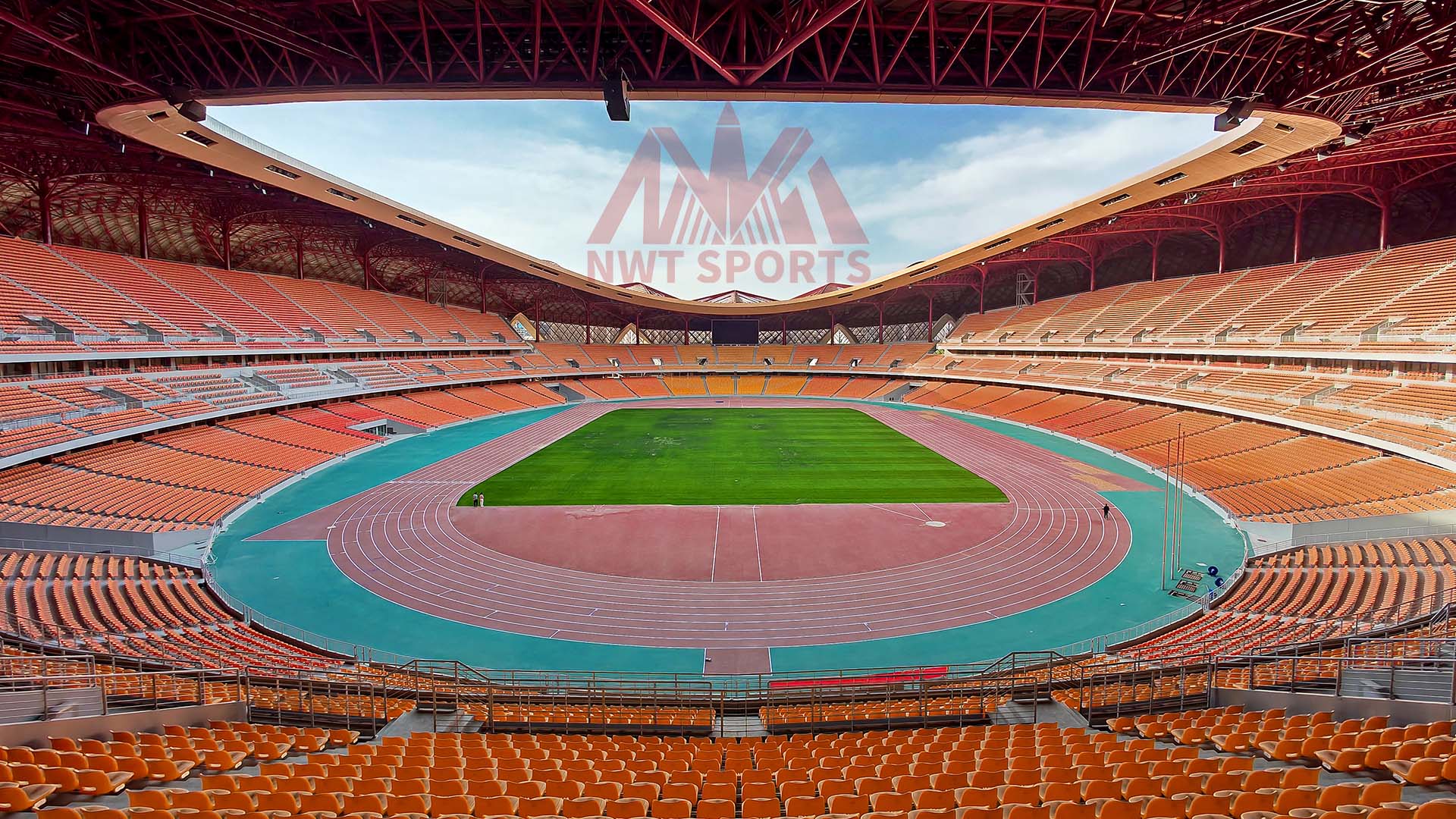

Running tracks are a fundamental component of athletic facilities worldwide, catering to both professional athletes and casual runners. If you're considering installing a 400m running track, understanding the dimensions, the different types of surfaces available, and the associated costs is essential. This article will provide a comprehensive guide to 400m running track dimensions, factors affecting installation costs, and insights into choosing the right installation company, with a spotlight on NWT Sports—your trusted partner in track construction.

400m Running Track Dimensions: Key Considerations

The standard 400m running track is an oval-shaped track consisting of two straight sections and two curved sections. These dimensions are recognized globally by athletic governing bodies, including the International Association of Athletics Federations (IAAF), which sets the regulations for track and field events.

1. Length: The total length of the track is 400 meters, measured 30cm from the inside edge of the track.

2. Width: A standard running track consists of 8 lanes, each lane being 1.22 meters (4 feet) wide. The total width of the track, including all lanes and the surrounding border, is approximately 72 meters.

3. Inner Radius: The radius of the curved sections is about 36.5 meters, which is a critical measurement to ensure that the track meets official standards.

4. Surface Area: The total area of a standard 400m running track, including the infield, is around 5,000 square meters. This large surface area is a key factor in determining installation costs.

Running Track Surface Types

Choosing the right surface material is crucial, as it impacts the performance, durability, and maintenance requirements of the track. The most common running track surfaces include:

1. Polyurethane (PU) Track: This is a popular choice for professional and collegiate tracks. It offers excellent shock absorption and traction, making it ideal for competitive events. PU tracks are durable but come at a higher cost due to the quality of materials used.

2. Rubberized Asphalt: This surface type is made by mixing rubber granules with asphalt, providing a cost-effective option for high-use facilities. While not as high-performance as PU tracks, rubberized asphalt is durable and suitable for schools and community tracks.

3. Polymeric Systems: These are advanced track surfaces composed of rubber and polyurethane layers. Polymeric tracks offer excellent performance and durability, making them a top choice for professional venues.

4. Synthetic Turf with Track Infill: Some facilities opt for a combination of synthetic turf and track infill, which is ideal for multi-use fields. This option provides versatility but may require more maintenance.

Factors Affecting Running Track Installation Costs

The cost of installing a 400m running track can vary significantly based on several factors. Understanding these factors can help you budget effectively and choose the right track for your needs.

1. Surface Material: As mentioned earlier, the choice of surface material plays a major role in determining the overall cost. PU and polymeric systems tend to be more expensive than rubberized asphalt due to their superior performance and durability.

2. Site Preparation: The condition of the installation site can greatly impact costs. If the site requires extensive grading, drainage, or base work, the cost will increase. Proper site preparation is essential to ensure the longevity and performance of the track.

3. Location: Geographic location can influence labor and material costs. Urban areas may have higher labor rates, while remote locations may incur additional transportation costs for materials and equipment.

4. Track Amenities: Additional features such as lighting, fencing, and spectator seating can add to the overall cost. While these amenities enhance the usability of the track, they should be factored into the budget during the planning phase.

5. Installation Company: The experience and reputation of the installation company also play a crucial role in determining costs. Working with an experienced company like NWT Sports ensures that you receive a high-quality track that meets your specifications and budget.

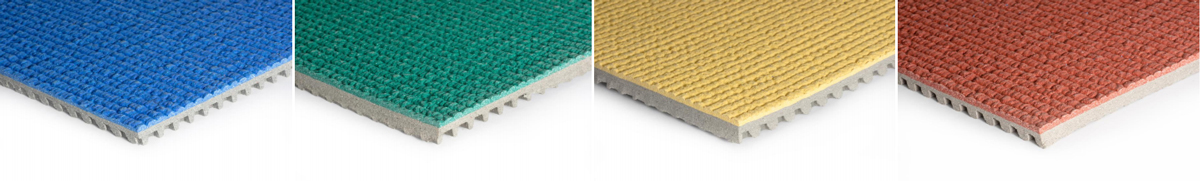

Prefabricated Rubber Running Track Color Card

How Much Does a Rubber Running Track Cost?

The cost of a rubber running track varies based on the factors outlined above. On average, you can expect to pay between $400,000 and $1,000,000 for a standard 400m track. Here’s a breakdown of typical costs:

1. Surface Material: The cost of the rubberized surface can range from $4 to $10 per square foot. For a 400m track, this translates to approximately $120,000 to $300,000.

2. Site Preparation and Base Work: Depending on the complexity of the site, preparation costs can range from $50,000 to $150,000.

3. Installation: Labor and installation costs typically range from $150,000 to $300,000, depending on the location and the track’s complexity.

4. Additional Features: Optional features like lighting, fencing, and drainage systems can add $50,000 to $250,000 to the overall cost.

Choosing the Right Running Track Installation Company

Selecting the right company to install your running track is just as important as the track itself. A reputable installation company will ensure that the track is constructed to the highest standards, with attention to detail that guarantees longevity and performance.

At NWT Sports, we bring years of experience and a proven track record of successful installations. Our team of experts is dedicated to delivering high-quality running tracks tailored to meet the specific needs of our clients. We pride ourselves on our ability to manage projects from conception to completion, ensuring that every detail is handled with the utmost care.

Why Choose NWT Sports?

1. Expertise: With over 100 running track installations across various venues, including schools, parks, and professional sports facilities, NWT Sports has the expertise to deliver top-tier results.

2. Quality Materials: We use only the highest quality materials, ensuring that your track is built to last. Whether you choose PU, rubberized asphalt, or a polymeric system, you can trust that your track will meet industry standards.

3. Customer-Centric Approach: At NWT Sports, our clients are our top priority. We work closely with you throughout the project to ensure that your vision is realized, and your expectations are exceeded.

4. Competitive Pricing: We offer competitive pricing without compromising on quality. Our transparent pricing model ensures that you know exactly what to expect, with no hidden fees.

Conclusion

Installing a 400m running track is a significant investment that requires careful planning and the right partners. By understanding the dimensions, surface options, and costs involved, you can make informed decisions that will benefit your facility for years to come. NWT Sports is here to guide you every step of the way, from initial design to final installation, ensuring that your track meets the highest standards of performance and durability.

If you're ready to take the next step in installing a top-quality running track, contact NWT Sports today for a consultation. Let us help you create a track that athletes will enjoy for years to come.

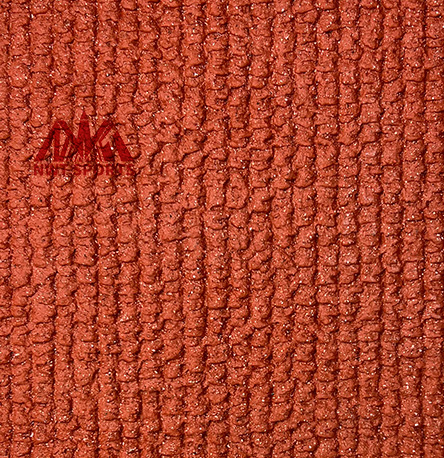

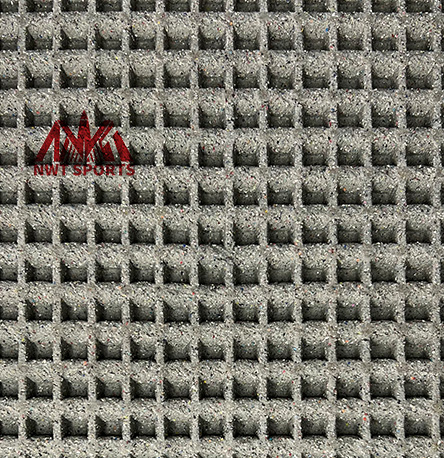

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Sep-04-2024