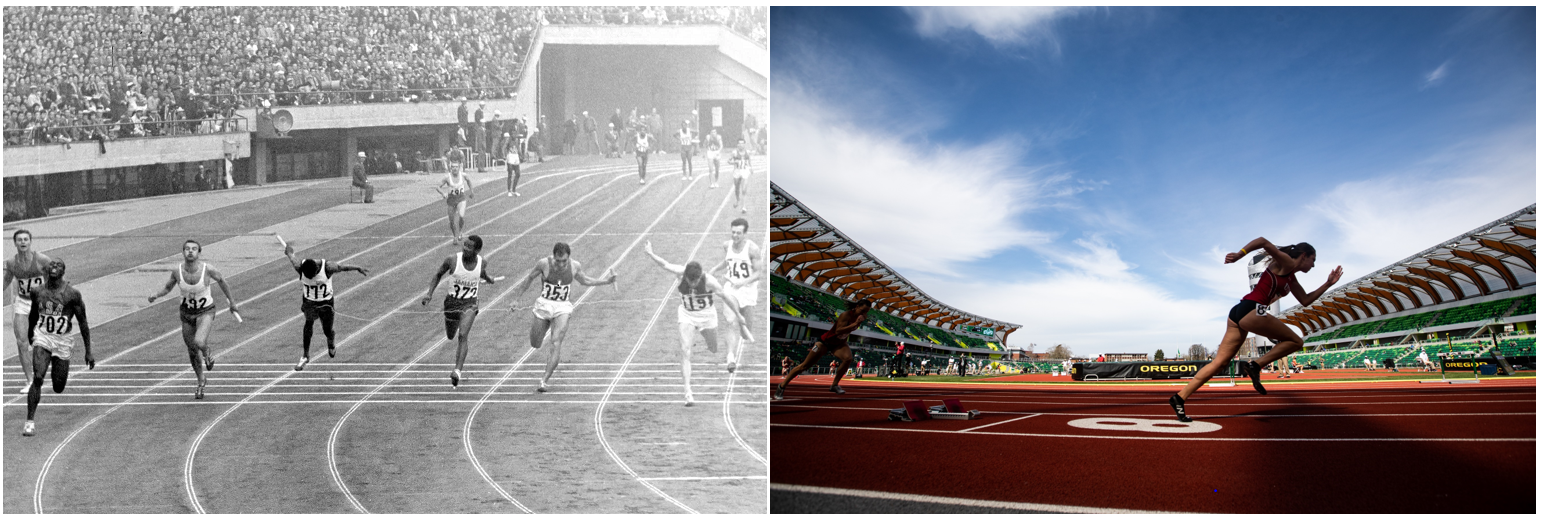

The history of Olympic running tracks reflects broader trends in sports technology, construction, and materials. Here's a detailed look at their evolution:

Ancient Olympics

- Early Tracks (circa 776 BC): The original Olympic Games held in Olympia, Greece, featured a single event called the stadion race, approximately 192 meters long. The track was a simple, straight dirt path.

Modern Olympics

- 1896 Athens Olympics: The first modern Olympic Games featured a running track in the Panathenaic Stadium, a straight 333.33-meter track made of crushed stone and sand, suitable for various races including the 100m, 400m, and longer distances.

Early 20th Century

- 1908 London Olympics: The track at White City Stadium was 536.45 meters long, incorporating a cinder surface, which provided a more consistent and forgiving running surface than dirt. This marked the beginning of the use of cinder tracks in athletics.

Mid 20th Century

- 1920s-1950s: The standardization of track dimensions began, with the most common length becoming 400 meters, featuring cinder or clay surfaces. The lanes were marked to ensure fairness in competition.

- 1956 Melbourne Olympics: The Melbourne Cricket Ground's track was made of compressed red brick and earth, indicative of the era's experimentation with various materials to improve performance.

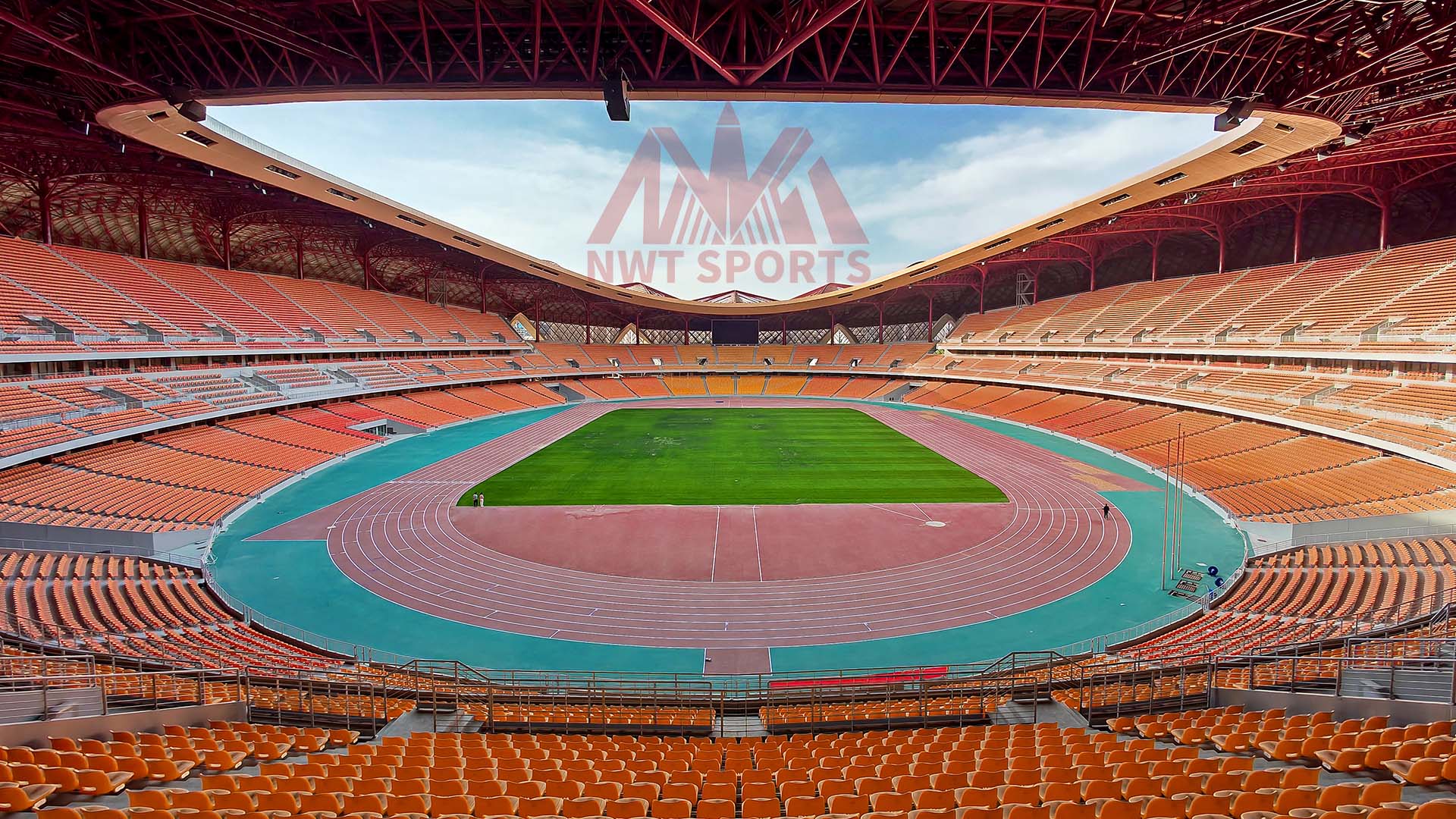

Synthetic Era

- 1968 Mexico City Olympics: This was a significant turning point as the track was made of synthetic material (Tartan track), introduced by the 3M Company. The synthetic surface provided better traction, durability, and weather resistance, significantly improving athletes' performances.

Late 20th Century

- 1976 Montreal Olympics: The track featured an improved synthetic surface, which became the new standard for professional tracks worldwide. This era saw significant improvements in track design, focusing on athlete safety and performance.

Modern Tracks

- 1990s-Present: Modern Olympic tracks are made of advanced polyurethane-based synthetic materials. The surfaces are designed for optimal performance, with cushioning to reduce the impact on runners' joints. These tracks are standardized at 400 meters in length, with eight or nine lanes, each 1.22 meters wide.

- 2008 Beijing Olympics: The National Stadium, also known as the Bird's Nest, featured a cutting-edge synthetic track designed to enhance performance and minimize injuries. These tracks often incorporate technology to measure athletes' times and other metrics accurately.

Technological Advances

- Smart Tracks: The latest advancements include the integration of smart technology, with embedded sensors to monitor performance metrics such as speed, split times, and stride length in real-time. These innovations help in training and performance analysis.

Environmental and Sustainable Developments

- Eco-friendly Materials: The focus has also shifted towards sustainability, with the use of eco-friendly materials and construction techniques to minimize environmental impact. Recyclable materials and sustainable manufacturing processes are becoming more common. Such as prefabricated rubber running track.

Prefabricated Rubber Running Track Parameters

| Specifications | Size |

| Length | 19 meter |

| Width | 1.22-1.27 meter |

| Thickness | 8 mm - 20 mm |

| Color: Please refer to the color card. Special color also negotiable. | |

Prefabricated Rubber Running Track Color Card

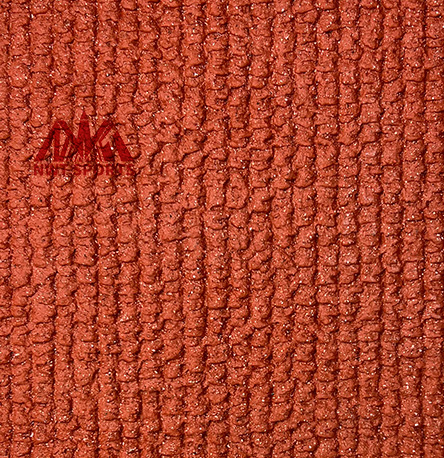

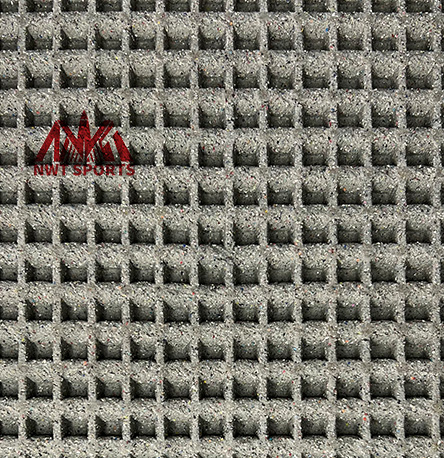

Prefabricated Rubber Running Track Structures

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Summary

The development of Olympic running tracks has mirrored advancements in materials science, engineering, and a growing understanding of athletic performance and safety. From simple dirt paths in ancient Greece to high-tech synthetic surfaces in modern stadiums, each evolution has contributed to faster, safer, and more consistent racing conditions for athletes around the world.

Post time: Jun-19-2024