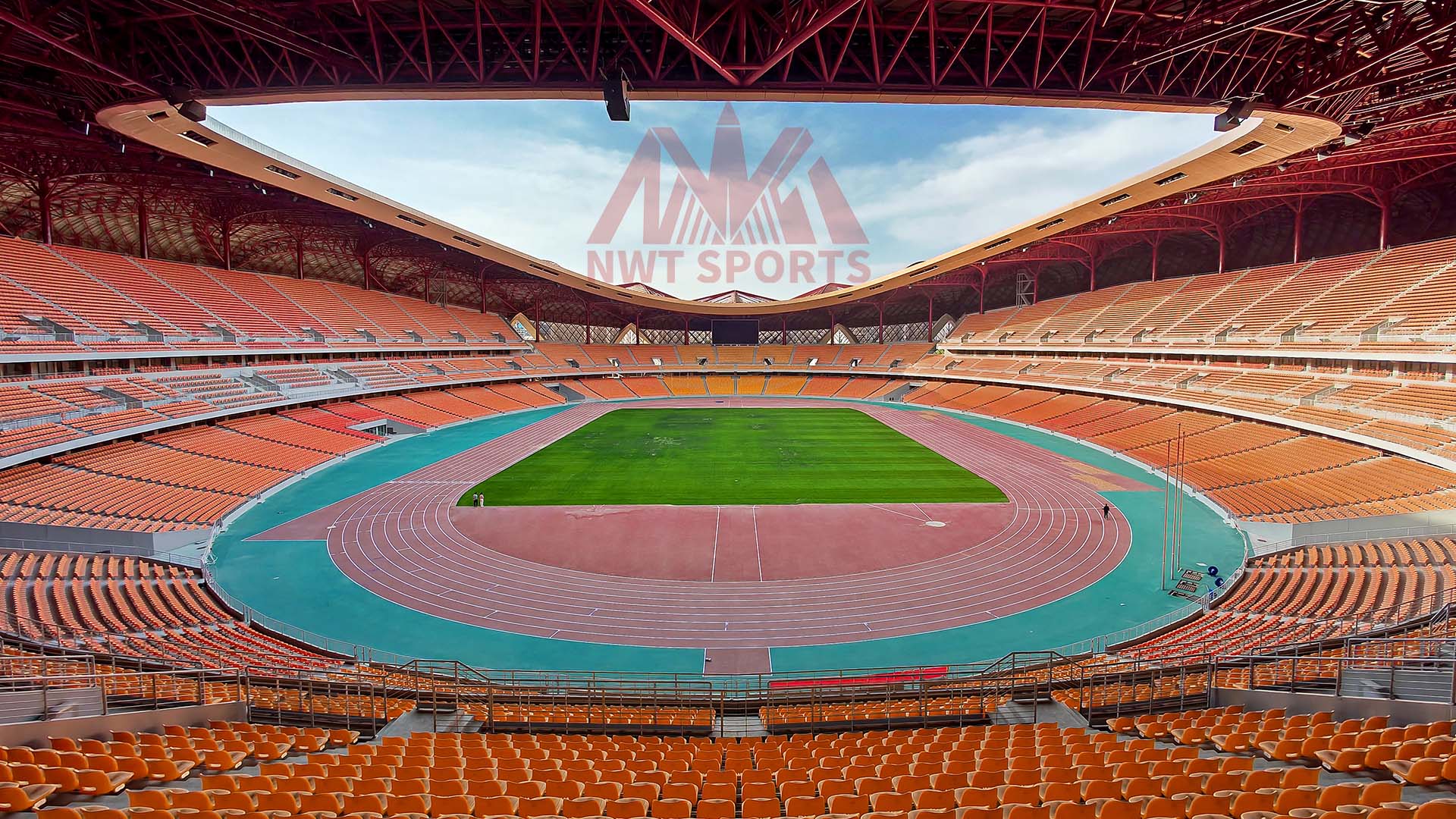

Prefabricated rubber tracks have emerged as a revolutionary solution in sports facility construction, offering numerous advantages over traditional track surfaces. Their adoption in international competitions highlights their superior quality, durability, and performance. This article explores the application of prefabricated rubber tracks in international events, focusing on their benefits and the advancements made by leading brands like NWT Sports.

Superior Performance in International Competitions

Prefabricated rubber tracks are engineered to meet the stringent requirements of international competitions. These tracks offer consistent performance, providing athletes with optimal traction, shock absorption, and stability. The uniform surface ensures fair competition conditions, which is crucial in events where every millisecond counts. Brands like NWT Sports have invested in advanced technology to produce tracks that maintain their integrity under high-intensity use, making them ideal for global sports events.

Durability and Longevity

International competitions demand surfaces that can withstand rigorous use over extended periods. Prefabricated rubber tracks are designed for durability, with high resistance to wear and tear. They are manufactured using high-quality recycled rubber and advanced binding agents that ensure the tracks remain intact despite heavy usage. This longevity reduces the need for frequent replacements, providing a cost-effective solution for event organizers.

Rapid Installation and Minimal Disruption

One of the standout benefits of prefabricated rubber tracks is their quick installation process. Traditional track surfaces can take weeks or even months to install, often leading to significant disruptions. In contrast, prefabricated tracks can be installed swiftly, minimizing downtime. This is particularly beneficial for international events, where timely preparation is critical. The modular nature of these tracks allows for precise and efficient installation, ensuring the venue is ready for use in a shorter timeframe.

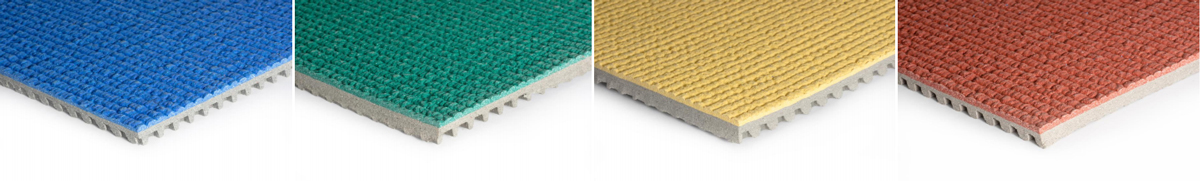

Prefabricated Rubber Running Track Color Card

Environmental Sustainability

With increasing emphasis on sustainability, the environmental benefits of prefabricated rubber tracks make them an attractive choice for international competitions. These tracks are often made from recycled materials, reducing waste and promoting eco-friendly practices. The production process is designed to minimize energy consumption and emissions, aligning with the global push towards greener sports facilities. NWT Sports, for instance, incorporates sustainable practices throughout its manufacturing process, reinforcing its commitment to environmental stewardship.

Case Studies of International Applications

Several high-profile international competitions have successfully implemented prefabricated rubber tracks. For example, the Olympics and World Athletics Championships have utilized these tracks, showcasing their reliability and performance. In these events, NWT Sports' prefabricated rubber tracks provided a consistent and high-quality surface, contributing to the athletes' outstanding performances and the overall success of the events.

Compliance with International Standards

Prefabricated rubber tracks are designed to comply with international standards set by governing bodies like the International Association of Athletics Federations (IAAF). These standards ensure the tracks provide a safe and fair environment for athletes. Compliance with such rigorous standards underscores the quality and reliability of prefabricated tracks, making them the preferred choice for international events.

Conclusion

The application of prefabricated rubber tracks in international competitions underscores their superior performance, durability, and environmental benefits. Brands like NWT Sports lead the way in providing high-quality track surfaces that meet the demands of global sports events. As the sports industry continues to evolve, the adoption of prefabricated rubber tracks is set to increase, driven by their proven advantages in enhancing athletic performance and promoting sustainability.

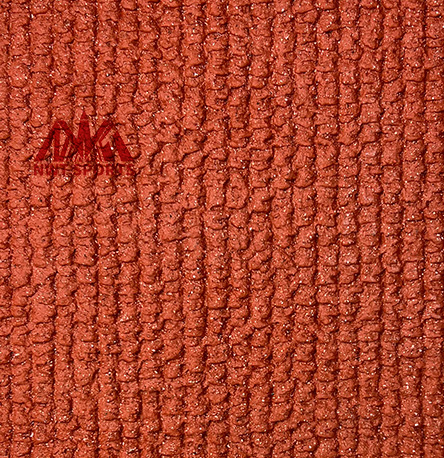

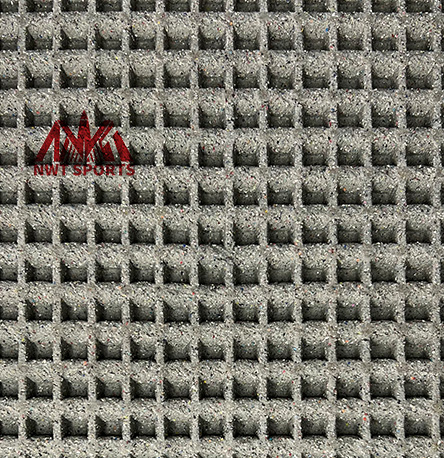

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jul-09-2024