Before construction, prefabricated rubber running tracks require a certain level of ground hardness, meeting the hardness standards before construction can proceed. Therefore, the subbase foundation of prefabricated rubber running tracks must be solidified.

Concrete Foundation

1. After completion of the foundation, the cement surface must not be too smooth, and there should be no phenomena such as sanding, peeling, or cracking.

2. Flatness: Overall pass rate should be above 95%, with a tolerance of within 3mm over a 3m straightedge.

3. Slope: Should meet sports technical specifications (lateral slope not greater than 1%, longitudinal slope not greater than 0.1%).

4. Compressive strength: R20 > 25 kg/square centimeter, R50 > 10 kg/square centimeter.

5. The foundation surface should be free of water blocking.

6. Compaction: Surface compaction density should be over 97%.

7. Maintenance period: Above 25°C outdoor temperature for 24 days; between 15°C and 25°C outdoor temperature for 30 days; below 25°C outdoor temperature for 60 days (watering frequently during the maintenance period to remove alkaline components from volatile cement).

8. Trench covers should be smooth and transition smoothly with the track without steps.

9. Before laying prefabricated rubber tracks, the base layer should be free of oil, ash, and dry.

Asphalt Foundation

1. The foundation surface must be free from cracks, obvious roller marks, oil stains, unblended asphalt chunks, hardening, sinking, cracking, honeycombing, or peeling.

2. The foundation surface should be free of water blocking.

3. Flatness: The pass rate for flatness should be above 95%, with a tolerance of within 3mm over a 3m straightedge.

4. Slope: Should meet sports technical specifications (lateral slope not greater than 1%, longitudinal slope not greater than 0.1%).

5. Compressive strength: R20 > 25 kg/square centimeter, R50 > 10 kg/square centimeter.

6. Compaction: Surface compaction density should be over 97%, with dry capacity reaching over 2.35 kg/liter.

7. Asphalt softening point > 50°C, elongation 60 cm, needle penetration depth 1/10 mm > 60.

8. Asphalt thermal stability coefficient: Kt = R20/R50 ≤ 3.5.

9. Volume expansion rate: < 1%.

10. Water absorption rate: 6-10%.

11. Maintenance period: Above 25°C outdoor temperature for 24 days; between 15°C and 25°C outdoor temperature for 30 days; below 25°C outdoor temperature for 60 days (based on volatile components in asphalt).

12. Trench covers should be smooth and transition smoothly with the track without steps.

13. Before laying prefabricated rubber running tracks, clean the foundation surface with water; the base layer should be free of oil, ash, and dry.

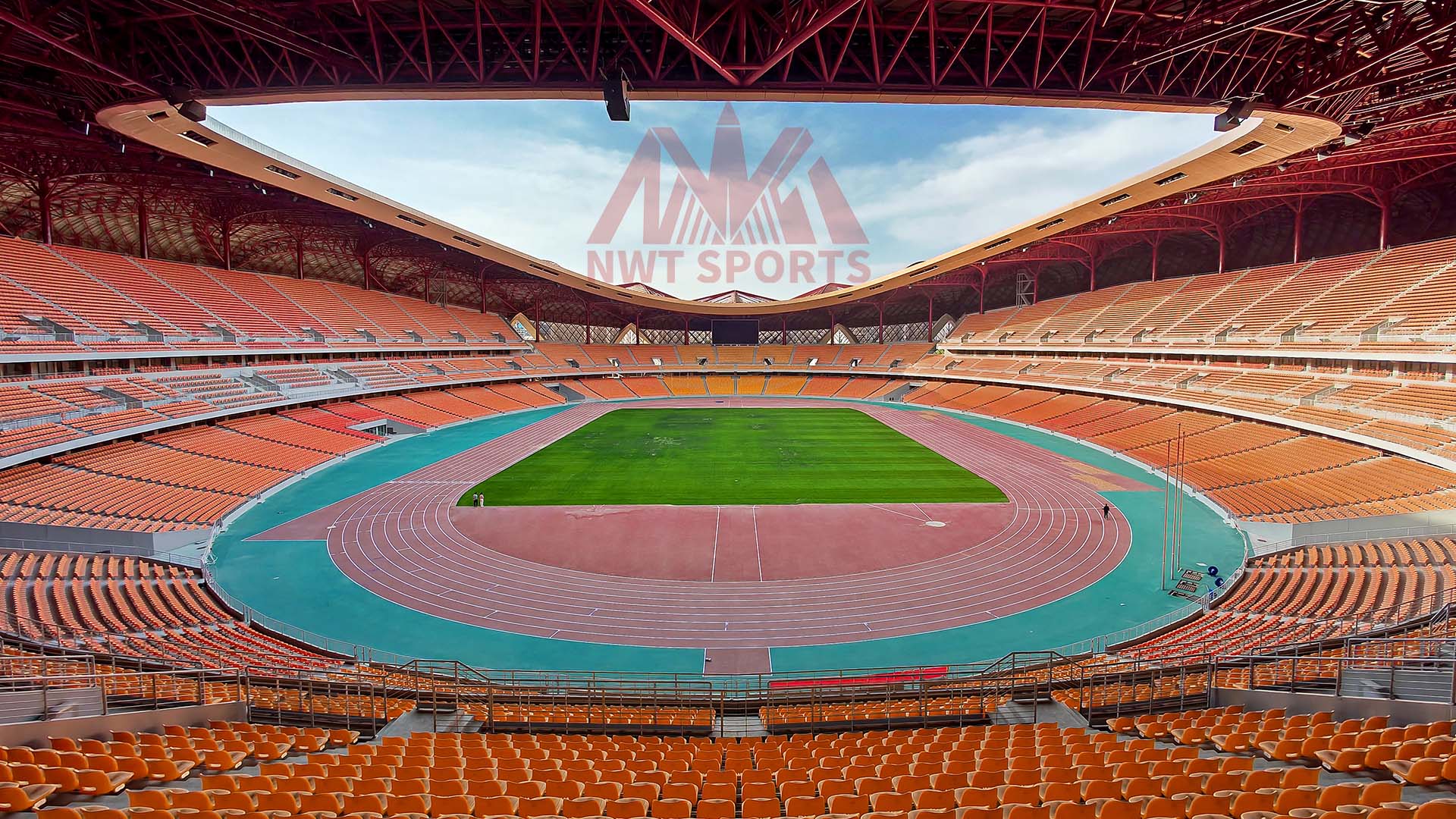

Prefabricated Rubber Running Track Application

Prefabricated Rubber Running Track Parameters

| Specifications | Size |

| Length | 19 meter |

| Width | 1.22-1.27 meter |

| Thickness | 8 mm - 20 mm |

| Color: Please refer to the color card. Special color also negotiable. | |

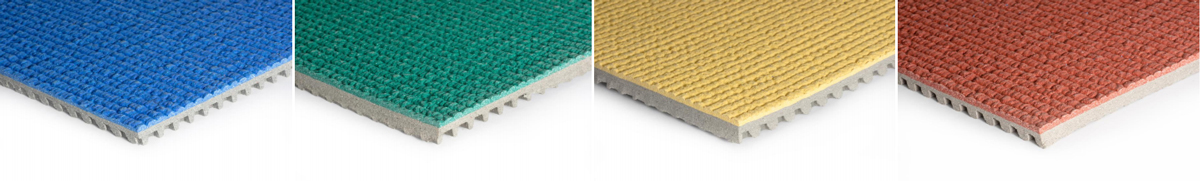

Prefabricated Rubber Running Track Color Card

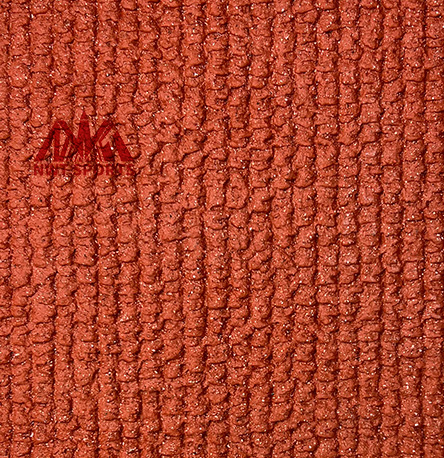

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

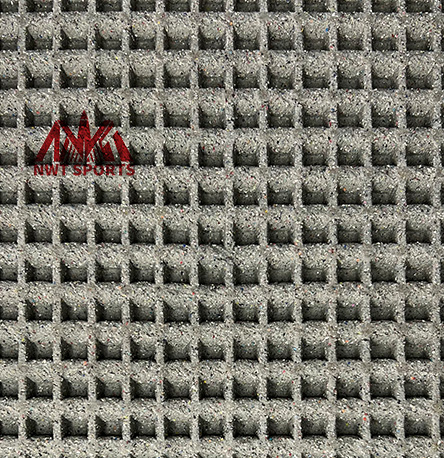

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jun-26-2024