Prefabricated rubber tracks are a popular choice for athletic facilities due to their durability, performance, and safety features. However, like any sports surface, they require proper maintenance and care to ensure longevity and optimal performance. NWT Sports, a leading brand in the industry, provides a comprehensive guide on maintaining and caring for your prefabricated rubber tracks. This article will explore best practices for maintaining these tracks, focusing on practical tips and SEO-friendly strategies to help facility managers keep their surfaces in top condition.

Importance of Regular Maintenance

Regular maintenance of prefabricated rubber tracks is crucial for several reasons:

· Longevity: Proper care extends the lifespan of the track, ensuring a good return on investment.

· Performance: Regular upkeep maintains the track’s optimal performance, providing athletes with a consistent and safe surface.

· Safety: Preventive maintenance helps identify and rectify potential hazards, reducing the risk of injuries.

Daily Cleaning and Inspection

Daily cleaning is the first step in maintaining a prefabricated rubber track. NWT Sports recommends the following daily practices:

1. Sweeping: Use a soft-bristled broom or a blower to remove debris, leaves, and dirt from the track surface.

2. Spot Cleaning: Address spills and stains immediately using a mild detergent and water. Avoid harsh chemicals that could damage the rubber.

3. Inspection: Conduct a visual inspection to identify any signs of wear, damage, or foreign objects that could harm the track or athletes.

Weekly and Monthly Maintenance

In addition to daily cleaning, weekly and monthly maintenance tasks are essential:

1. Deep Cleaning: Use a pressure washer with a wide nozzle to thoroughly clean the track. Ensure the water pressure is not too high to avoid damaging the surface.

2. Edge Cleaning: Pay attention to the edges and perimeter of the track, where debris tends to accumulate.

3. Joint Inspection: Inspect the seams and joints for any separation or damage and repair as necessary.

4. Surface Repairs: Address minor cracks or gouges promptly with suitable repair materials recommended by NWT Sports.

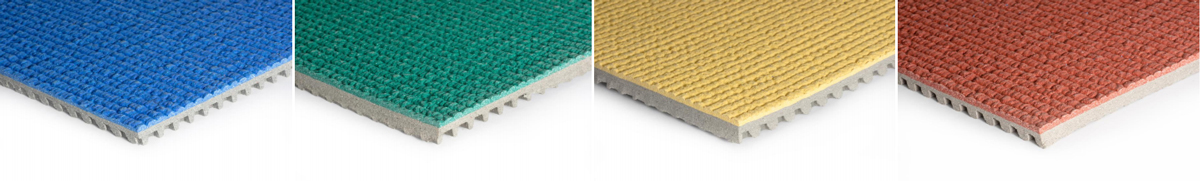

Prefabricated Rubber Running Track Color Card

Seasonal Maintenance

Seasonal changes can affect the condition of prefabricated rubber tracks. NWT Sports suggests the following seasonal maintenance tips:

1. Winter Care: Remove snow and ice promptly using plastic shovels and avoid salt or harsh chemicals that can deteriorate the rubber.

2. Spring Checkup: After winter, inspect the track for any freeze-thaw damage and perform necessary repairs.

3. Summer Protection: During hot months, ensure the track is kept clean and consider applying UV protective coatings if recommended by the manufacturer.

4. Fall Preparation: Clear leaves and organic matter regularly to prevent staining and decomposition on the track surface.

Long-term Care and Professional Maintenance

For long-term care, NWT Sports recommends professional maintenance services:

1. Annual Inspections: Schedule annual professional inspections to assess the track's condition and perform deep cleaning and major repairs.

2. Resurfacing: Depending on usage and wear, consider resurfacing the track every 5-10 years to restore its performance and appearance.

3. Warranty and Support: Utilize NWT Sports' warranty and customer support services for maintenance advice and technical assistance.

Best Practices for Track Use

Proper use of the track also plays a role in its maintenance:

1. Footwear: Ensure athletes use appropriate footwear to minimize surface damage.

2. Prohibited Items: Restrict the use of sharp objects, heavy machinery, and vehicles on the track.

3. Event Management: For large events, implement protective measures such as mats or covers to prevent damage from heavy foot traffic and equipment.

Conclusion

Maintaining and caring for prefabricated rubber tracks is essential to maximize their lifespan and performance. By following the guidelines provided by NWT Sports, facility managers can ensure their tracks remain in excellent condition, providing a safe and high-quality surface for athletes. Regular cleaning, timely repairs, seasonal care, and professional maintenance are all key components of an effective maintenance strategy.

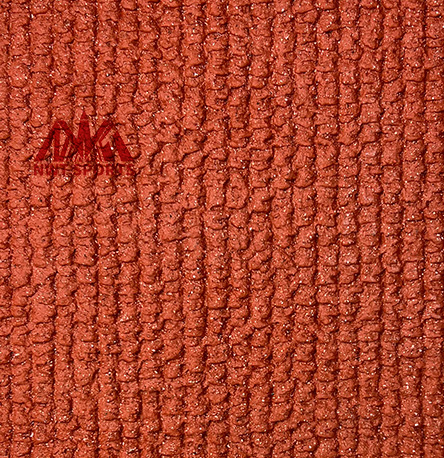

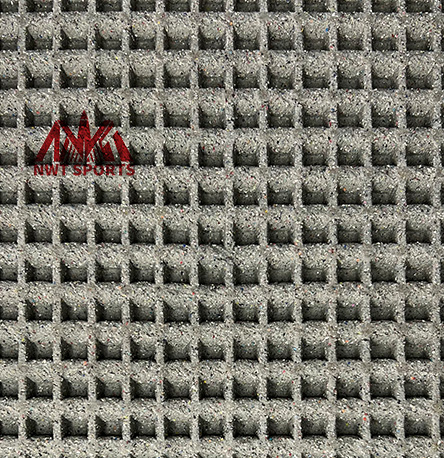

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jul-11-2024