Running is a popular form of exercise that can be enjoyed both indoors and outdoors. Each environment offers unique benefits and challenges, and choosing between indoor jogging tracks and outdoor jogging track flooring depends on personal preferences and fitness goals. Let’s explore the advantages and disadvantages of both options to help you decide which is better for you.

Indoor Jogging Tracks

Pros:

1. Controlled Environment: Indoor jogging track flooring provide a stable climate free from weather-related interruptions. This can be particularly beneficial in extreme temperatures or during inclement weather, ensuring that your workout routine remains consistent year-round.

2. Reduced Impact: Indoor tracks often feature cushioned surfaces that reduce the impact on your joints. This can be advantageous for those recovering from injuries or for individuals with joint sensitivities.

3. Safety: Running indoors eliminates concerns about traffic, uneven surfaces, and other outdoor hazards. This makes indoor jogging tracks a safer option, especially during early morning or late evening hours.

4. Convenience: Many gyms and fitness centers have indoor jogging tracks, allowing you to combine your run with other workout routines. This convenience can save time and make it easier to stick to your fitness plan.

Cons:

1. Monotony: Running on indoor jogging tracks can become monotonous due to the lack of changing scenery. This can make it harder to stay motivated during longer runs.

2. Air Quality: Indoor environments might have less fresh air circulation compared to outdoor settings. This can impact your breathing, especially during intense workouts.

Outdoor Jogging Tracks

Pros:

1. Scenic Variety: Outdoor jogging tracks offer diverse scenery and changing environments, which can make your runs more enjoyable and mentally stimulating. This variety can enhance motivation and prevent workout boredom.

2. Fresh Air: Running outdoors provides access to fresh air, which can improve lung function and overall respiratory health. The natural surroundings can also have a positive impact on your mental well-being.

3. Natural Terrain: Outdoor jogging tracks offer varied terrain that can help improve balance and strengthen different muscle groups. This can lead to a more well-rounded fitness routine.

4. Vitamin D: Exposure to sunlight during outdoor runs helps your body produce vitamin D, which is essential for bone health and immune function.

Cons:

1. Weather Dependency: Outdoor jogging tracks are subject to weather conditions. Extreme temperatures, rain, snow, or strong winds can disrupt your running routine and make outdoor running less appealing.

2. Safety Concerns: Running outdoors can pose safety risks, including traffic, uneven surfaces, and potential encounters with strangers or animals. It’s important to choose safe, well-lit paths and stay aware of your surroundings.

3. Impact on Joints: Hard surfaces like concrete or asphalt on outdoor jogging tracks can be harsh on your joints, potentially leading to injuries over time.

Conclusion

Both indoor jogging tracks and outdoor jogging tracks have their own set of advantages and disadvantages. If you prioritize a controlled, safe environment with less impact on your joints, indoor jogging tracks might be the better choice. On the other hand, if you enjoy scenic variety, fresh air, and natural terrain, outdoor jogging tracks could be more appealing.

Ultimately, the best option depends on your personal preferences, fitness goals, and lifestyle. You might even choose to incorporate both indoor and outdoor jogging tracks into your routine to enjoy the benefits of each. Happy running!

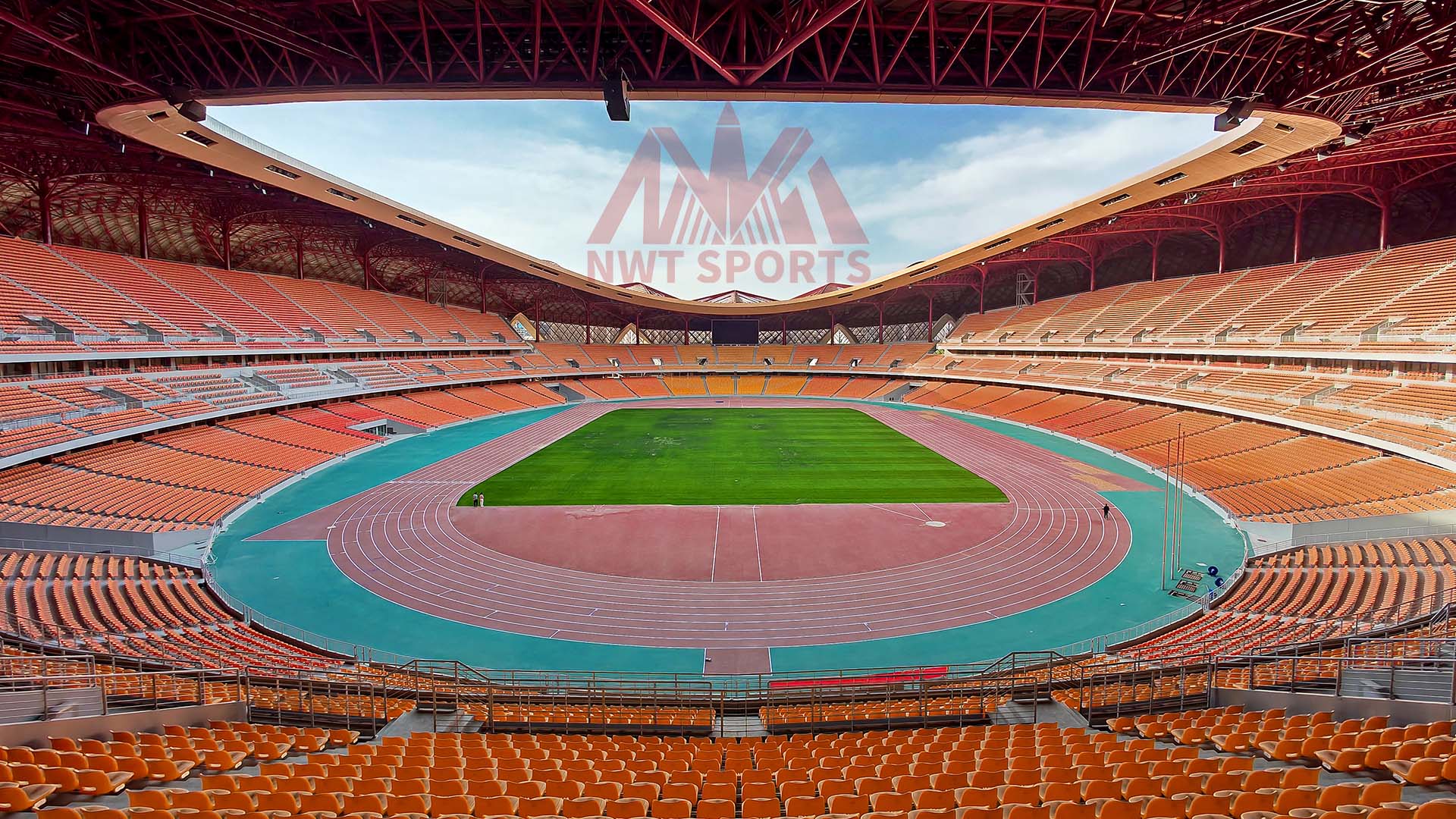

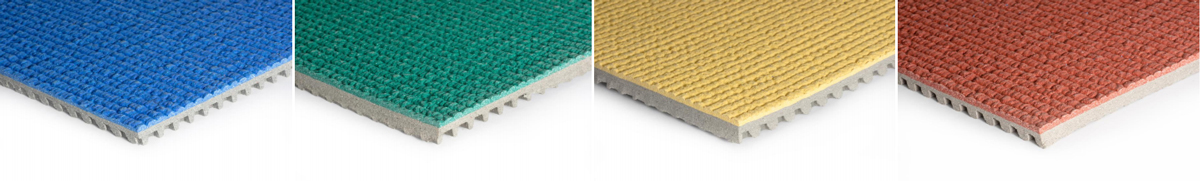

Prefabricated Rubber Running Track Structures

Prefabricated Rubber Running Track Details

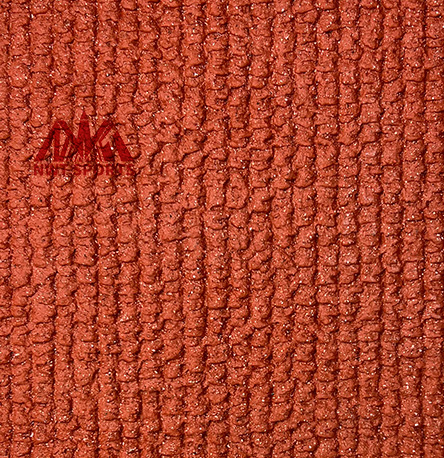

Wear-resistant layer

Thickness: 4mm ±1mm

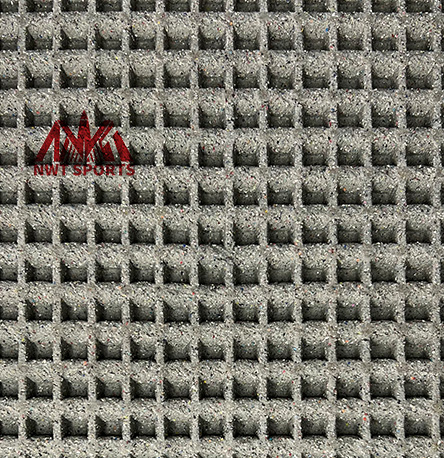

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jun-21-2024