In today's society, environmental sustainability has become an imperative across all industries, including sports facility construction. Prefabricated rubber tracks, as a burgeoning material for athletic surfaces, are increasingly scrutinized for their environmental certifications and adherence to standards. Let's delve into several key aspects regarding the environmental certification and standards for prefabricated rubber tracks.

Material Selection and Environmental Impact

Prefabricated rubber tracks typically utilize recycled rubber as their primary material. This rubber is often sourced from discarded tires and other recycled rubber products, processed into high-quality track surfaces through advanced manufacturing techniques. This process not only reduces waste accumulation but also conserves virgin resources, aligning with principles of sustainable development.

Environmental Considerations in Production Processes

During the manufacturing of prefabricated rubber tracks, environmental standards encompass various facets. These include energy efficiency, water resource management, waste handling, and emissions reduction. Manufacturers employ advanced production technologies and equipment to minimize energy consumption and emissions, ensuring compliance with environmental regulations and standards.

Environmental Certifications and Compliance Standards

To ensure the environmental performance and safety of prefabricated rubber tracks, various international certification and standards systems are in place. For instance, ISO 14001 certification for Environmental Management Systems guides manufacturers in achieving best practices for environmental protection throughout the production process. Additionally, specific environmental standards for sports facility materials may be established in certain countries or regions to minimize the environmental and health impacts during usage. Such as ISO9001, ISO45001.

ISO45001

ISO9001

ISO14001

Driving Forces for Sustainable Development

The environmental certifications and standards for prefabricated rubber tracks not only address the environmental impacts of the product itself but also reflect the commitment of manufacturers and users to sustainable development. Choosing track materials that meet environmental standards not only reduces operational costs and extends lifespan but also enhances athlete experience and safety, contributing to the sustainable development of campus and community sports facilities.

In conclusion, environmental certification and standards for prefabricated rubber tracks serve as crucial drivers pushing the industry towards environmentally friendly and sustainable practices. Through rigorous material selection, environmentally conscious production processes, and compliance with certifications, prefabricated rubber tracks not only meet the functional requirements of sports facilities but also make positive contributions to environmental protection and the sustainable future of society.

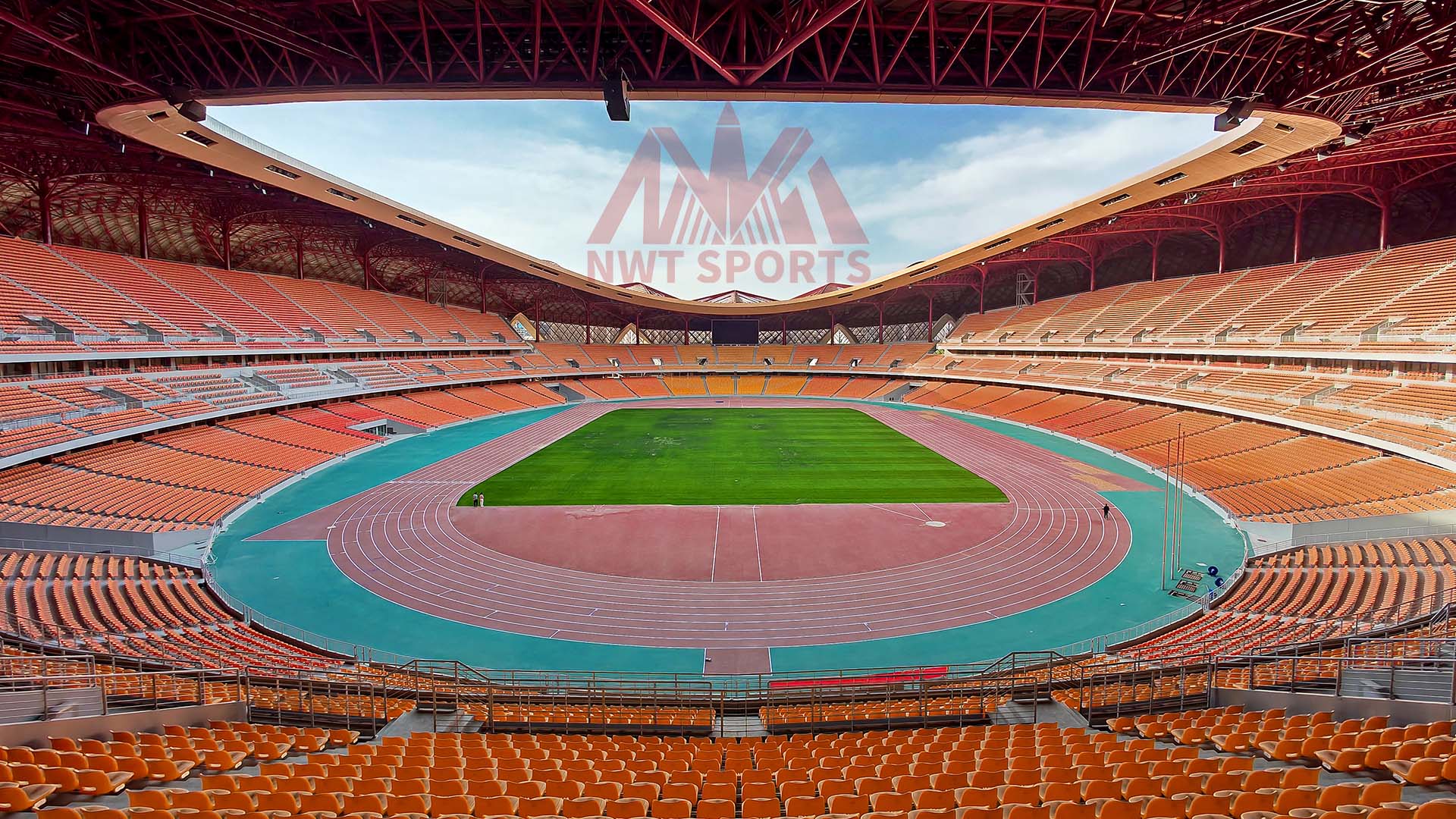

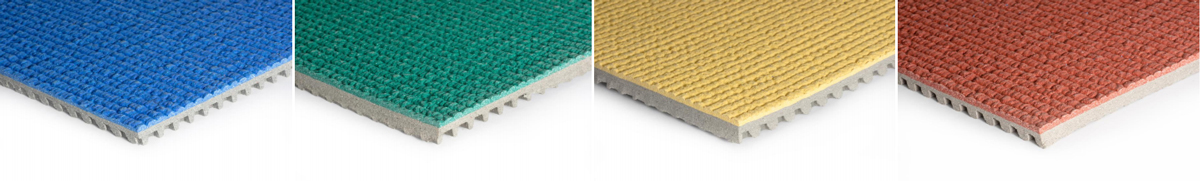

Prefabricated Rubber Running Track Color Card

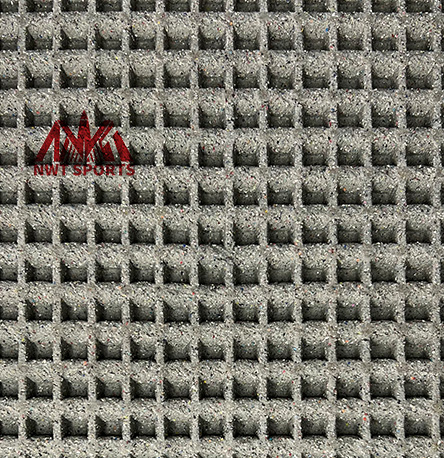

Prefabricated Rubber Running Track Structures

Our product is suitable for higher education institutions, sports training centers, and similar venues. The key differentiator from 'Training Series' lies in its lower layer design, which features a grid structure, offering a balanced degree of softness and firmness. The lower layer is designed as a honeycomb structure, which maximizes the degree of anchoring and compaction between the track material and the base surface while transmitting the rebound force generated at the moment of impact to the athletes, thereby effectively reducing the impact received during exercise, and This is transformed into forwarding kinetic energy, which improves the athlete's experience and performance.This design maximizes the compactness between the track material and the base, efficiently transmitting the rebound force generated during impacts to athletes, converting it into forward kinetic energy. This effectively reduces the impact on joints during exercise, minimizes athlete injuries, and enhances both training experiences and competitive performance.

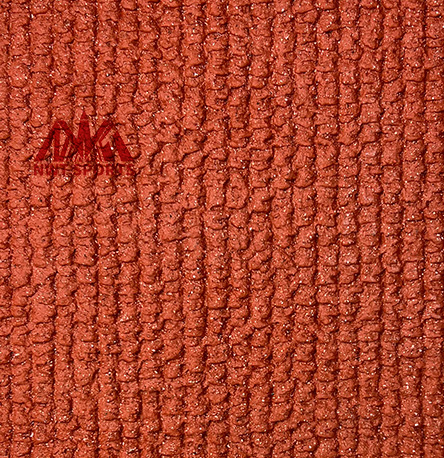

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

Post time: Jul-04-2024